citationsquirrel

Well-known member

As you may recall, I decided a while back that I would make myself a furled leader jig so that I could start making furled leaders during our long Minnesota winters, along with tying flies. So, I did some online research and downloaded a lot of articles. Then I procrastinated for a while.  This past week I did some more thinking on my design and this weekend I purchased a few of the supplies that I’ll need and actually started. I thought I would document the build here for everyone to enjoy. So, I’ll post some details and pictures as I go along. I think I have a couple original design ideas to share. It is going to be a bit of a lengthy process because, (1) I’m in no hurry, (2) I’m hoping to have my son help me with a few of the steps, (3) I’m not expecting to have a long time period that I can dedicate to the project – more like 15 or 20 minutes here and there when I get a chance, and (4) fine craftsmanship takes time.

This past week I did some more thinking on my design and this weekend I purchased a few of the supplies that I’ll need and actually started. I thought I would document the build here for everyone to enjoy. So, I’ll post some details and pictures as I go along. I think I have a couple original design ideas to share. It is going to be a bit of a lengthy process because, (1) I’m in no hurry, (2) I’m hoping to have my son help me with a few of the steps, (3) I’m not expecting to have a long time period that I can dedicate to the project – more like 15 or 20 minutes here and there when I get a chance, and (4) fine craftsmanship takes time.

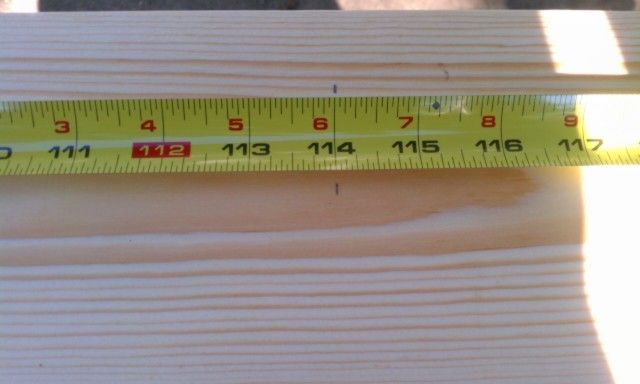

The first thing I started with was the pegs. For this I’m using a 1” dowel. I need five pegs. I cut myself five pieces at 4¼” long. All of the plans I found suggested using 4” pegs, but I figured after I got done with my sanding, they would be somewhere in between. I used a handsaw to cut them, so their bases were not all exactly level. So, I’m sanding the bases to level them off. After all, I don’t want to have crooked pegs. I’m also sanding the tops of the pegs. This will give me a nice smooth and rounded top for all my pegs. I have one peg currently done and am going to be working on the other four.

Will our hero survive? Will all the pegs have rounded tops? Tune in next time as our adventure continues.

The first thing I started with was the pegs. For this I’m using a 1” dowel. I need five pegs. I cut myself five pieces at 4¼” long. All of the plans I found suggested using 4” pegs, but I figured after I got done with my sanding, they would be somewhere in between. I used a handsaw to cut them, so their bases were not all exactly level. So, I’m sanding the bases to level them off. After all, I don’t want to have crooked pegs. I’m also sanding the tops of the pegs. This will give me a nice smooth and rounded top for all my pegs. I have one peg currently done and am going to be working on the other four.

Will our hero survive? Will all the pegs have rounded tops? Tune in next time as our adventure continues.