random user

Well-known member

I'm posting this up because I am looking for advice, tips, trick, etc that people are willing to share.

(No need to be gentle with liberal application of The 2x4 o' Enlightenment.)

This is bid 1 for me. Started by stripping a 8'6" Pflueger 5 weight that the only thing I am really sure of is that it was well used by 1994.

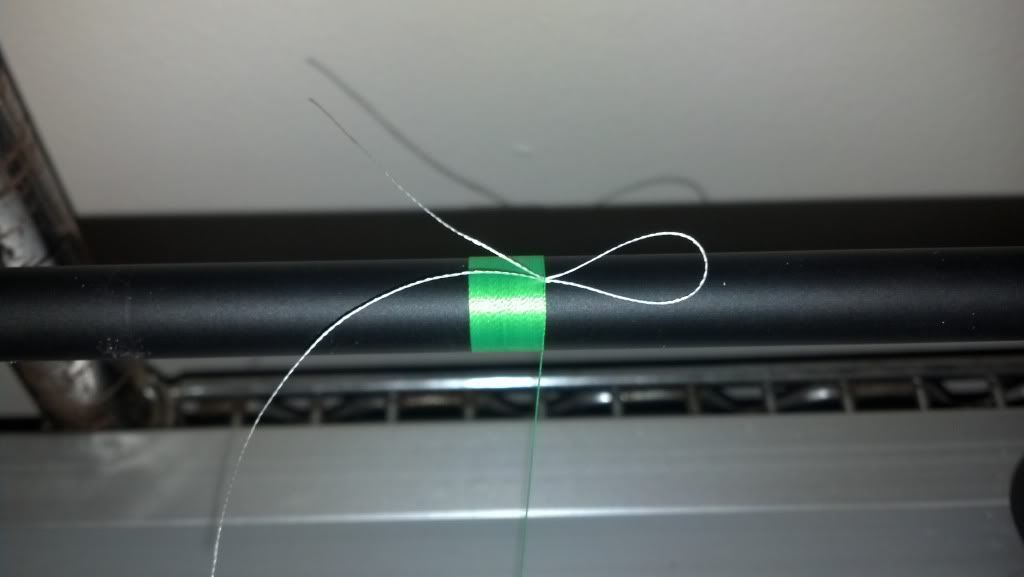

These are the first wraps for me. Thread is rayon embroidery thread.

Not the most glorious of victories, but it's a win for me - guide is super tight.

Color choices weren't so well thought out. Will probably change up to a dark and light olive or something similar.

Probably should have started with the tougher "A" nylon instead of the more fragile rayon. Skipping the trim bands the first time around might have been a good idea too, but an ugly win is still a win.

(No need to be gentle with liberal application of The 2x4 o' Enlightenment.)

This is bid 1 for me. Started by stripping a 8'6" Pflueger 5 weight that the only thing I am really sure of is that it was well used by 1994.

These are the first wraps for me. Thread is rayon embroidery thread.

Not the most glorious of victories, but it's a win for me - guide is super tight.

Color choices weren't so well thought out. Will probably change up to a dark and light olive or something similar.

Probably should have started with the tougher "A" nylon instead of the more fragile rayon. Skipping the trim bands the first time around might have been a good idea too, but an ugly win is still a win.

Last edited: